For over 40 years, Butterworth Laboratories has provided independent, contract analytical services to the global pharmaceutical and related industries.

Pharmaceutical Testing Experts | Butterworth Laboratories

Since 1974, Butterworth Laboratories has provided independent, contract analytical chemistry services to the global pharmaceutical and related industries. Consequently, we are considered leaders in Quality Control Testing, Method Development, Method Validation, Method Transfer, and Stability Testing of pharmaceutical raw materials and finished products.

Comprehensive Contract Pharmaceutical Testing – Science on Demand

We build partnerships with our customers. They not only recognise our expertise and service but also value our integrity and impartiality. Understanding the challenges of modern pharmaceutical manufacturing processes and just-in-time production methods means that we can fit seamlessly into your supply chain. We are happy to discuss how we can organise testing your excipients and APIs to your schedule. Just contact us using the enquiry button above

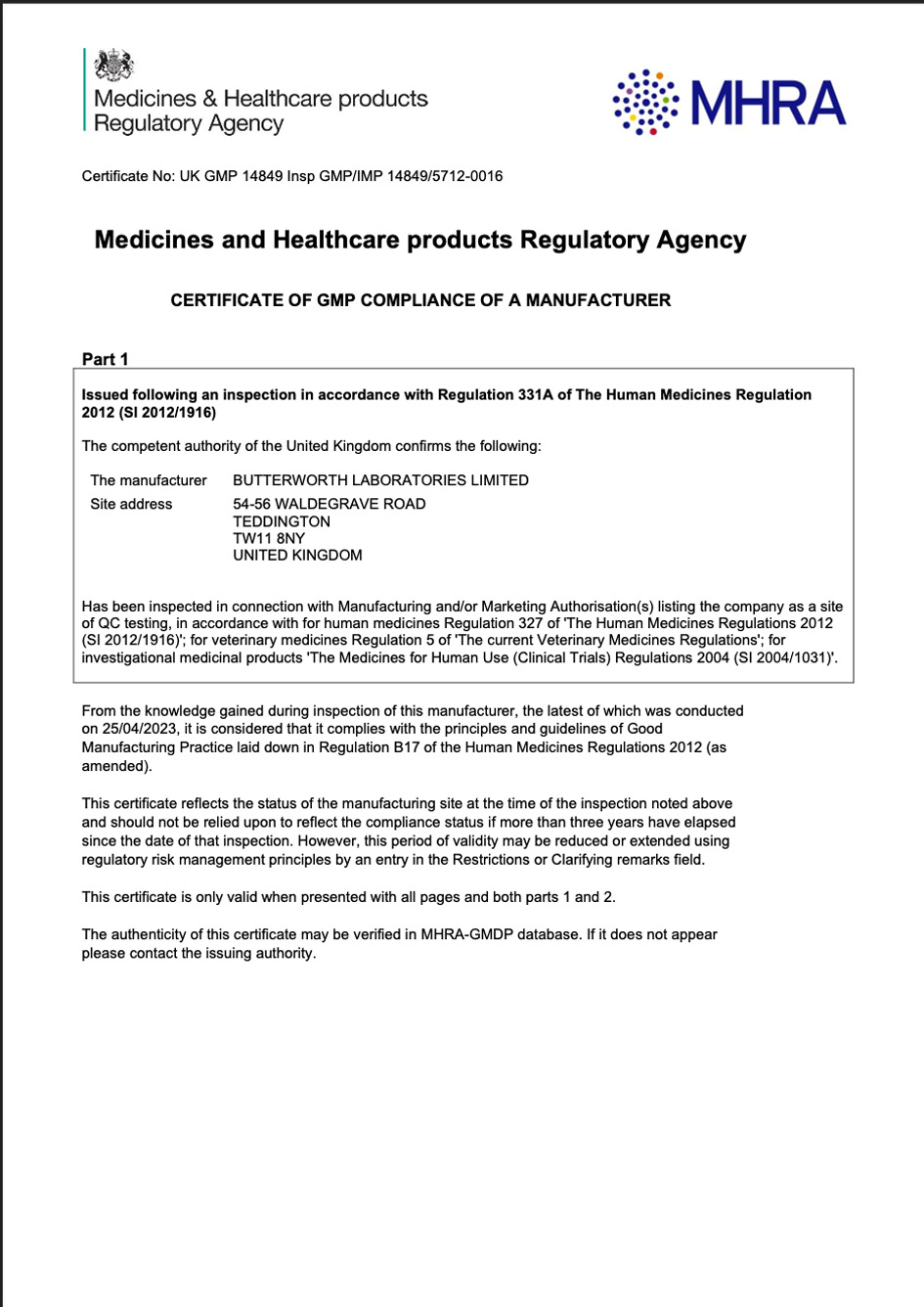

MHRA and FDA approval ensures that the service you receive is at the very highest level for cGMP analysis in pharmaceutical testing. Our Quality Assurance team ensures that these high levels are maintained to give you every confidence in us. Your pharmaceutical testing will always be completed to best-in-class standards. We enjoy hosting audits and are happy to make time for you at a time to suit you. We have experience with remote audits in addition to the more conventional in-person audit. So, if circumstances or economics make a remote audit preferable, you can count on us.

Excellence • Collaboration • Professionalism

Add 50 years of experience to your laboratory

The latest technology combined with our expert team of scientists make us leaders in Quality Control Testing, Method Development, Validation and Stability Storage, and Testing of both pharmaceutical raw materials and finished products.

Request a quote Make an enquiryOur Key Testing Applications

Allow your laboratory to innovate

The latest technology combined with our expert team of scientists make us leaders in Quality Control Testing, Method Development, Method Validation and Stability Testing of both pharmaceutical raw materials and finished products.

We refine this service by promoting a culture of open communication between our analysts and our clients, ensuring that you retain control of your work.

Request a quote Make an enquiry