For over 40 years, Butterworth Laboratories has provided independent, contract analytical services to the global pharmaceutical and related industries.

Would you like salt and vinegar on your chips?

23 February 2023

The answer is NO if the chips are mounted on a printed circuit board (PCB).

Manufacturers of PCBs have long understood the correlation between surface cleanliness and corrosion, electrochemical migration, dendritic growth and the resultant, current leakage, and shorting. This means that clean room technology utilised by the industry is very stringent and far exceeds the level of hygiene required by the food industry for example. Not surprisingly, since electrical charge and current are involved, contaminants of interest are ionic in nature including six cations e.g. Sodium, seven anions e.g. Chloride, and seven Weak Organic Acid residues e.g. Acetate. Butterworth Laboratories can identify and quantify many such detrimental species in accordance with the Institute for Printed Circuits standard IPC-TM-650 method 2.3.28.

In the lab, PCBs under examination are sealed in a small, non-leaching plastic extraction bag, along with a minimum volume of extraction solvent, ensuring that the entire surface of the PCB is in contact with the solvent. The bag is suspended in a water bath and incubated for one hour and the extracts are then analysed by Ion Chromatography (IC) with Conductivity Detection. One method is required for cations and another for anions and acids. The methods generally have adequate sensitivity to determine contaminants at µg/mL levels in solution.

Alternatively, the client may swab an area of the PCB and then send swabs to the lab for testing.

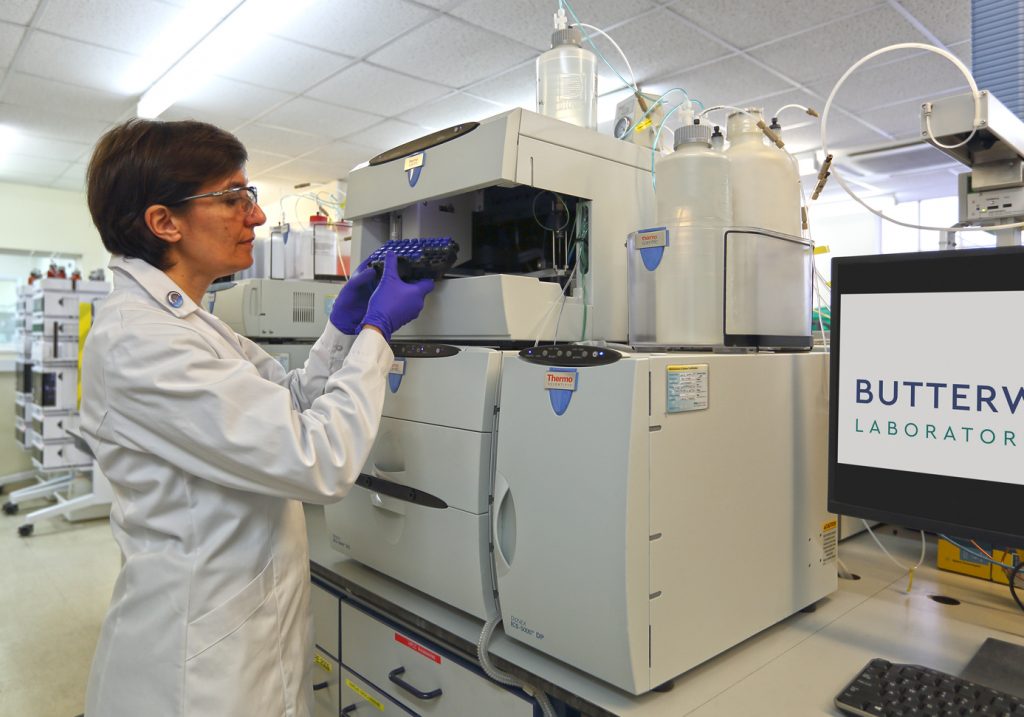

Butterworth has experience in IC testing going back to the 1980’s and currently has 3 state-of-the-art IC systems.

Frank Judge – Consultant Chemist- Chromatography at Butterworth Laboratories Ltd

Kat Jones – Team Leader – Ion Chromatography & Elemental Microanalysis