For over 40 years, Butterworth Laboratories has provided independent, contract analytical services to the global pharmaceutical and related industries.

Exhaustive Extraction Doesn’t Need to Take a Lifetime or Cost the Earth

3 November 2022

Polymeric artificial human joints are an example of a permanent contact medical devices. Since such devices are routinely sterilised using ethylene oxide (EO) after manufacture, it is a requirement of ISO 10993-7 to determine the lifetime average daily release of the resultant EO residues. This is calculated by dividing the total residue mass determined in the sample by 25,000. This is the assumed patient lifetime in days defined in the standard.

The traditional approach has been to complete a time-consuming and expensive extended cycle of 24-hour water extractions followed by analysis which is continued until less than 10% of residual ethylene oxide is found compared to the first extraction cycle. The solution to this problem is Multiple Headspace Extraction (MHE) gas chromatography (GC).

By definition, MHE-GC is a method of calibration that can be used when all ‘normal’ approaches would fail. Normal in this context, would be a known concentration of analyte in a matrix that matches the sample under consideration. MHE is applied to solid samples which are insoluble and therefore exclude the application matrix-matched calibration standards. Normal calibration relates GC peak area to a known amount of analyte.

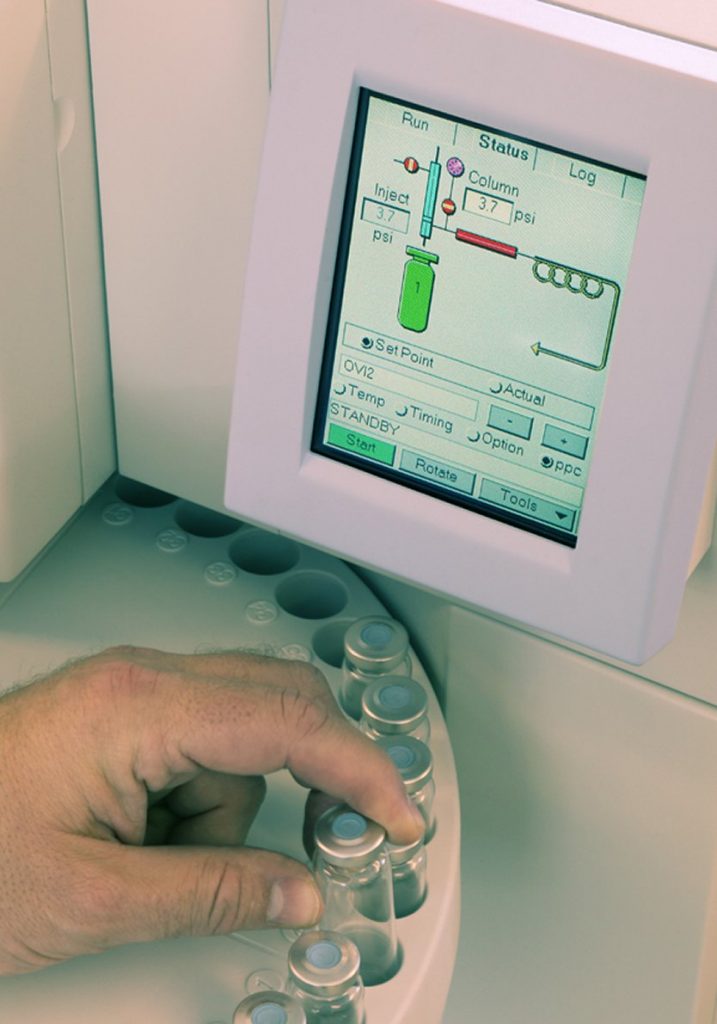

With MHE a small volume (say 10µL) of ethylene oxide in a non-reactive solvent such as dimethyl acetamide (DMAC), is inoculated into a headspace vial as a reference standard. The sample preparation is simply a small mass (say 1g) in a headspace vial which is then inoculated with the same small volume of pure DMAC. This means that there is virtually no time spent in sample preparation and only a single preparation is required. Standard and sample vials are then incubated and analysed a number of times (say 4) with venting of the vial pressure after injection onto the GC each time.

The sample and standard vials give a declining peak area with each cycle of incubation, injection and venting. A plot of Log (Area) vs Injection Cycle Number is then constructed for sample and standard and should give straight lines which are extrapolated to y = 0. The areas enclosed under the plots are then compared and thus calibration is achieved. The only requirement is that the standard is totally vapourised and that the plots give straight lines assuring sample to standard proportionality.

One last consideration is required concerning the vial volume occupied by the solid sample. This must be accounted for in calculation, or a piece of inert material such as glass beads with the same volume as the sample to be can be added to standard vials. However, the most eloquent solution is simply to use an internal standard.