For over 40 years, Butterworth Laboratories has provided independent, contract analytical services to the global pharmaceutical and related industries.

Hypromellose and other cellulose-type assays

30 April 2024

For decades, Butterworth has been using hydriodic acid in the form of the Zeisel reaction to strip the

methoxy, ethoxy and hydroxypropoxy groups off various cellulose backbones. The assay of

hypromellose, methyl-, ethyl- and hydroxypropyl cellulose type samples to the Ph.Eur., USP, JP and

ChP involves a complex and hazardous reaction via the adipic acid catalysed cleavage of the alkoxy

group from the cellulose backbone with hydriodic acid and subsequent formation of the alkyl iodide

which itself is used as the targeted analyte. The reaction is carried out with the hydriodic acid at

elevated temperatures. This analysis certainly puts the reaction vial, cap and septa to the test.

Over the years, BLL has trained many analysts in the assay and has witnessed a number of changes

in the form and scope of the test. From the wet chemistry test to the packed column GC test with

FID or TCD to its current incarnation as a capillary column GC assay with FID or TCD. However, within

the JP, there still exists one monograph that embraces the old packed column technology,

Hypromellose acetate succinate.

You would be forgiven for thinking that the move to capillary GC is a sign of the times and an

improvement in the test. On the contrary. This must be the only test where we GC analysts at BLL

yearn for the classic packed column approach, if only for the methoxy part, which occasionally

produces slightly inferior precision using capillary columns. We put this down to split discrimination.

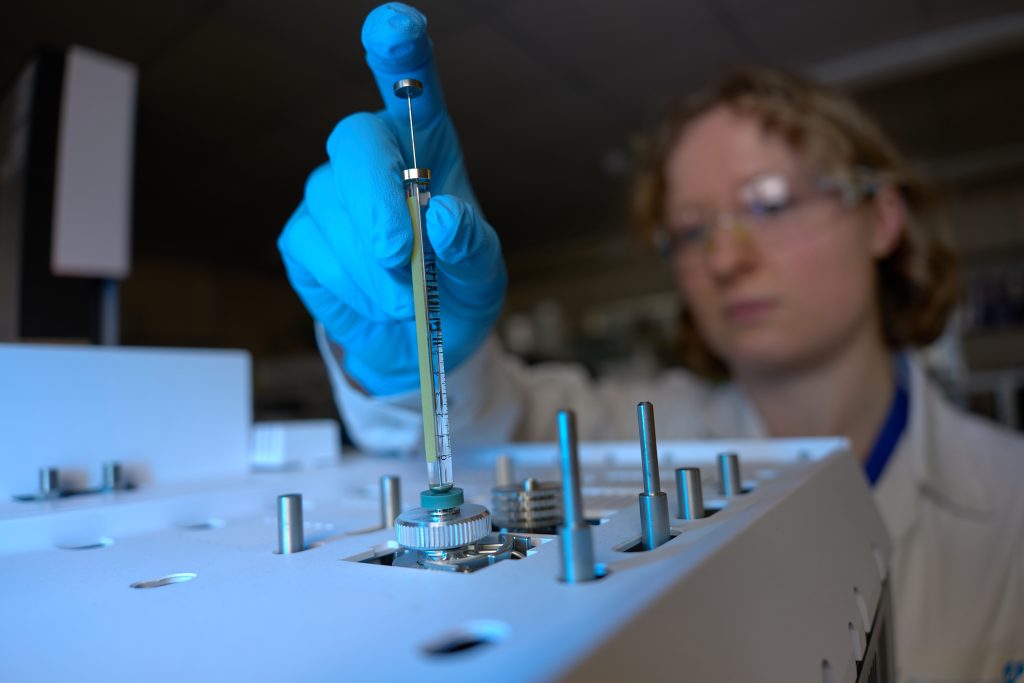

In spite of the hazards associated with the test, it has always been and still is a favourite test for our

GC analysts to perform as it involves “proper” chemistry rather than a simple weigh and dilute. To

add to the hands-on nature our analysts get to show off their manual injection technique, which,

believe it or not, is far superior in precision and replication than any GC autosampler. The internal

standard certainly helps, of course.

Due to the precision, we obtain for each of the analytes (<1.0% manual injections), we have opted to

tighten the pharmacopoeia’s system suitability requirement of 2.0% RSD (n=6) for the hypromellose

monograph. The reason being is that the specification for substitution type 2910 is 28.0 – 30.0% for

methoxy groups. Such a large precision requirement for such a tight specification can inevitably

result in out-of-specification results for those samples manufactured at the lower end of the

specification. Indeed, this has occurred on several occasions and in conjunction with one of our clients we proposed and agreed to tighten the RSD requirement to 1.0% for all hypromellose testing, irrespective of the substitution type. This gives us, and of course, our clients, greater

Our expertise in this test over the years has resulted in many of our clients