For over 40 years, Butterworth Laboratories has provided independent, contract analytical services to the global pharmaceutical and related industries.

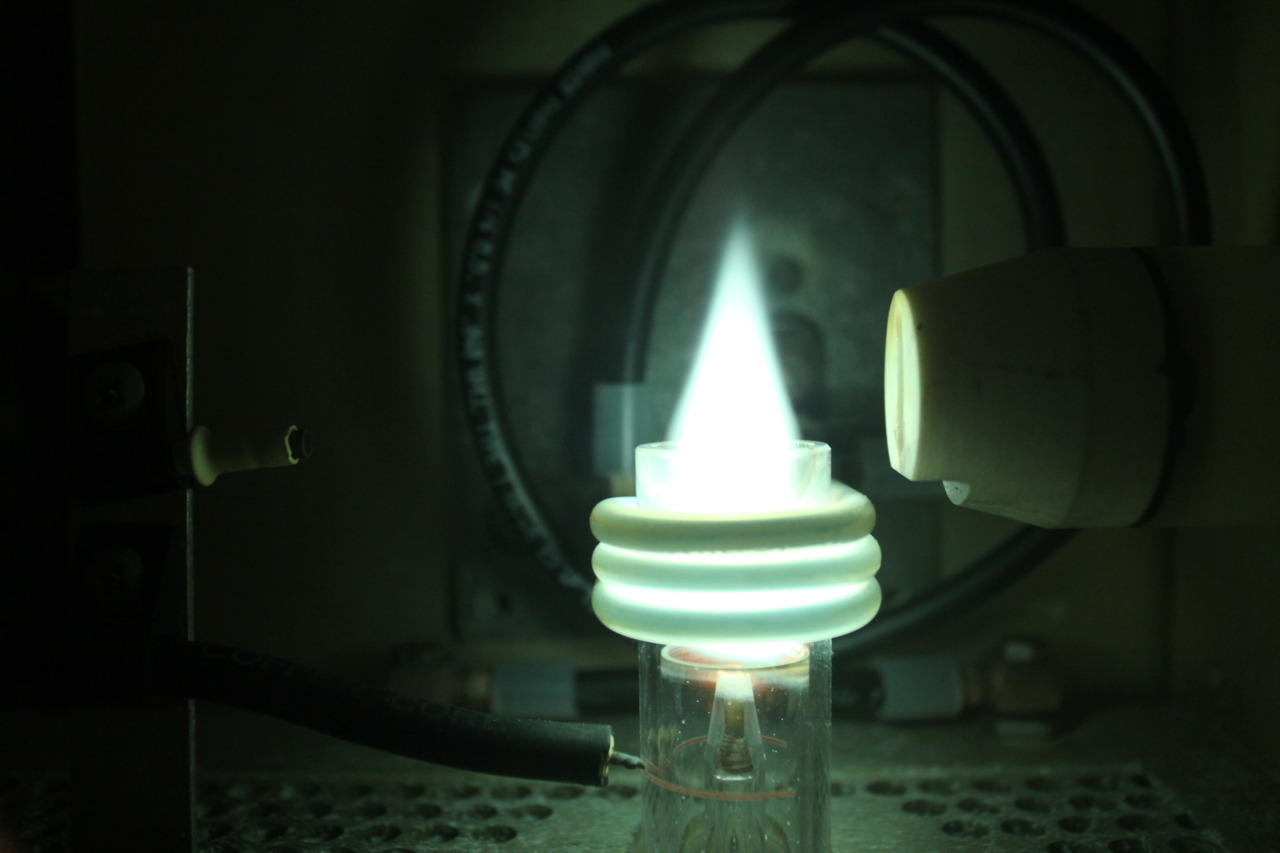

Inductively Coupled Plasma-Optical Emission Spectroscopy

10 December 2024

As part of our occasional series of articles explaining some of the key analytical techniques we use at Butterworth, we thought it would be useful to provide some background information on one of our main instruments used for metals analysis.

Inductively Coupled Plasma-Optical Emission Spectroscopy (ICP-OES) is a technique used to determine trace elements in a wide range of both liquid and solid sample types. It can provide highly precise and accurate results as long as the correct care and attention are applied during both sample preparation and instrument analysis. ICP-OES is a useful tool that can be used for limit testing and assays as part of both identification and impurity testing. One of the main benefits of the ICP-OES is its ability to analyse a wide range of multiple elements simultaneously, allowing the user to make one set of standard and sample solutions, saving both time and, therefore, expenses. The instrument run time is also much quicker than that of other instruments, such as the ICP-MS.

The basic principle of ICP-OES uses energy from a plasma to excite electrons in an atom to a higher energy state. When these electrons relax back to the initial ground state, they emit photons at specific wavelengths characteristic of the element in question. The amount of light emitted can be used to calculate the concentration of analyte. This is done by preparing a series of calibration standards at known concentrations and plotting a calibration curve.

Sample solutions can be prepared in various ways, including aqueous dissolution, microwave digestion, open vessel digestion, solvent dissolution and HF analysis. The final solution must be clear, complete and free from undigested material. The ICP-OES can tolerate much higher concentrations of acid than other trace metal techniques, as well as higher concentrations of the analyte itself.

The ICP-OES is capable of detecting low-level analytes in the ppm/ppb range (however, it may not be appropriate for determining low-level elemental impurities where the ICP-MS is better suited). Due to this, it is therefore susceptible to contamination, and every care should be taken to reduce this possibility. Here at Butterworth Laboratories, a dedicated team of analysts work in a designated space when preparing all solutions. In addition to this, all preparations are completed using vessels and equipment specific to metal analysis. Furthermore, additional cleaning, such as soaking vessels in weak acid solutions, can be implemented for the more common analytes such as iron.

One potential issue with ICP-OES analysis that must be considered is interference. Interference can be physical, chemical, or spectral. The sample matrix can potentially cause interference; however, steps can and are taken to minimise these effects. These include matrix matching the sample solution to the calibration blank/standard solutions and the use of an internal standard. It is common practice to analyse multiple wavelengths and then select the best emission line based on several QC factors, but it is also important to ensure no spectral interference is visible in the peak shape, often seen as shoulders. Additionally, a spike can be a useful indicator of the success of the analysis; poor spike recoveries can suggest possible sample matrix effects and/or issues with the preparation method used. At Butterworth Laboratories, we can offer ICP-OES testing using generic in-house methods that meet the requirements of the pharmacopoeia general chapters and bespoke, material-specific, validated methods developed with our in-house project team. We have also successfully transferred methods that have historically proved challenging from the AAS to the ICP-OES. The ICP-OES is a powerful analytical technique that can be utilised for a wide range of testing and may be suitable for your future analysis.

Meghann Simcock – Analytical Chemist