For over 40 years, Butterworth Laboratories has provided independent, contract analytical services to the global pharmaceutical and related industries.

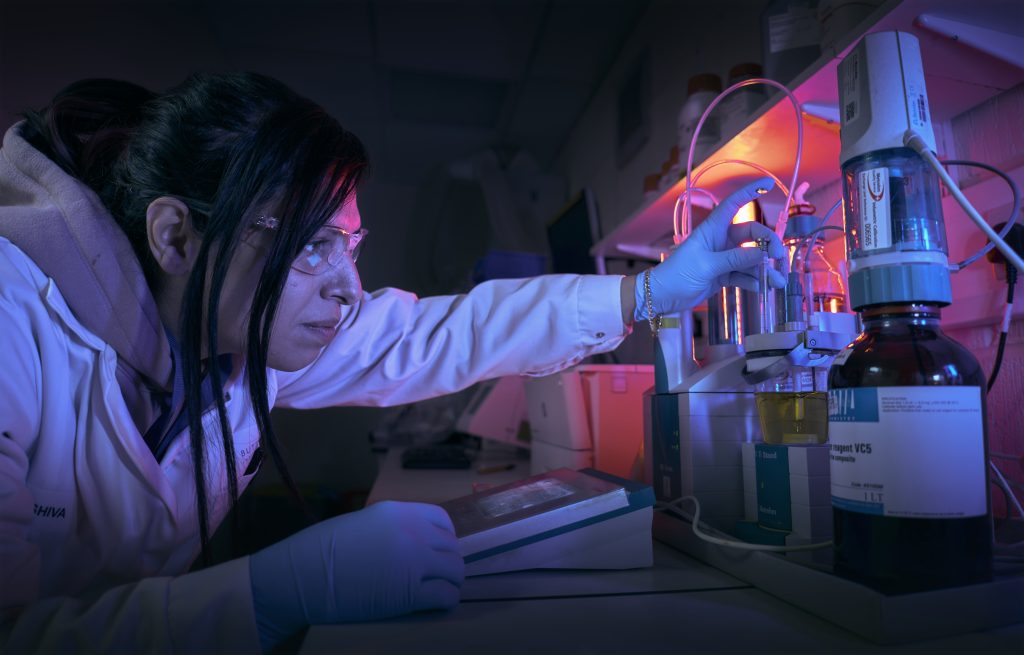

Karl Fischer, simple but complex

31 July 2024

Karl Fischer’s (KF) water determination is a vital and well-established method, but it can be fraught with difficulties and complexities. A material’s water content is often used to correct assays or other tests to give results on an anhydrous basis. So, no matter how good the assay itself is, the whole analysis may be compromised if the water result is off.

Let’s quickly look at the technique and then discuss some potential issues and how to overcome them.

There are two broad types of KF analysis: volumetric (or semi-micro) and coulometric (or micro) analysis. Both can use direct sample introduction or indirect addition after dissolution in an appropriate solvent or an oven attachment to ensure the water present is fully quantified.

Volumetric analysis is essentially a titration using a standardised KF titrant against the sample dissolved in a dried solvent. The endpoint is detected by a platinum electrode when iodine is in excess (as part of the Bunsen reaction between iodine, sulphur dioxide and water).

Coulometric determination uses the same chemistry as volumetric analysis; however, the reaction is performed electrochemically rather than through direct titration.

The following are considerations for both methods:

Direct addition: this is where the sample is added directly to the cell for titration. The sample may be a solid, liquid or gas. This is generally the most common method of analysis, but there are three main drawbacks to consider;

1) The sample must dissolve completely. Some methods will advise a suitable solvent mix, but many do not. Some information can be obtained from instrument manufacturers, or a trial-and-error approach can be applied. At least one component of the solvent must be miscible with water. Gentle warming can also be applied to aid dissolution, but care must be taken to ensure refluxing does not occur as this can add additional water from the atmosphere or cell (although the cell will be sealed and a desiccant used to dry air being pulled into the cell, this will not completely preclude all erroneous moisture addition). Sufficient time must be allowed to ensure complete dissolution. But where a significant amount of time is required, it is essential to apply correction for background drift. Butterworth has developed its own methodology for the analysis of hydrated salts, as these can often be problematic due to long dissolution time.

The solvent or solvent mix used must be the same as the one used when the instrument is standardised to ensure it reflects the sample system. A spike of water added to the sample/solvent mix can be useful to confirm instrument performance in the applicable matrix.

In a few cases, if you are only interested in surface or ‘free’ water, it may not be necessary to dissolve the sample – you will only need to extract it. Obtaining good precision for such analysis will give confidence that all applicable water is determined.

2) Side reactions can occur, which result in false high results. The classic example is aldehydes and ketones, which slowly react with KF reagents to produce water. Specialist reagents are available for this. Other examples include excessively acidic or basic samples, where additional buffering may be needed, and long-chain hydrocarbons, which may need specific reagents. Reactions can also be seen where samples saturate the solvent and affect the electrochemistry, leading to false low results as the instrument believes the endpoint has been reached early. This can often be visibly apparent as the KF reagent becomes dark in colour.

3) Handling and other contamination issues. Directly adding a sample to the cell means, in many cases, that air (which contains moisture) is also introduced. Often this is insignificant, but can become a problem where a sample is difficult to handle, such as a sticky liquid or a powder affected by static or clumps. Analyst care and experience will help with this and a process blank may be considered. Consideration also needs to be taken if the sample is hygroscopic; transfer from the balance to the instrument needs to be rapid and controlled and, in extreme cases, may require a protective atmosphere.

Indirect addition is where a sample is dissolved in a solvent before introduction into the KF system. For example, a volume of the dissolved sample is injected into the KF system. This method has the advantage of allowing the use of a wider range of solvents where sample dissolution may otherwise not be possible. It can also be useful for samples that are tricky to handle or those that are reactive to air.

Oven. This attachment drives off water from the sample and blows it directly into the KF system. This means the sample never directly enters the KF system, so potential side reactions and transfer problems are avoided. Care needs to be taken with the temperature setting. If it is too cold, not all the water of hydration will be released. If it is too hot, the sample may break down and combustion products will be transferred to the KF cell and side reactions can occur. Setting correct endpoint criteria and time is important so titration does not stop early.

Karl Fischer is an excellent technique, but careful consideration needs to be taken when setting up the instrument parameters and methodology. Sometimes, when problems are suspected with KF analysis, it can be useful to fall back on classic Loss on Drying analysis. Although this method will also detect other solvents present, the vast majority of the time, only moisture will be present, so it can be a useful comparison.

Due to the potential pitfalls of KF analysis, verifying compendial methods and validation for non-compendial testing to give confidence in results is always worth considering. We at Butterworths are experienced in providing this service.

Tim Goddard

Laboratory Manager – Inorganic and General Chemistry