For over 40 years, Butterworth Laboratories has provided independent, contract analytical services to the global pharmaceutical and related industries.

Metals testing to test your mettle: Vape liquids

17 December 2024

Since e-cigarette and vape devices were introduced, their popularity has sky-rocketed. Initially brought in as a ‘diet’ version of regular tobacco smoking, with emphasis on being a way to wean smokers off their habit, vaping has grown ever more prevalent, particularly amongst the younger population. Vape liquids contain nicotine and flavourings with a mixture of polyethylene glycol (PG) and vegetable glycerine (VG) as the solvent. When dispensed into a vape device, this saturates a wicking material in the coil, which is then heated to produce an inhaled vapour.

Over the years, more and more information has been released calling into question the safety of this habit, in particular with the shocking news of dangerous levels of Lead, Nickel and Chromium found in the vape liquids of devices confiscated from school pupils in 2023. High levels of these heavy metals can affect the central nervous system and brain development in young people and even lead to cancer.

But how did these levels get to be in there?

Here in the UK, regulations set out by the Tobacco & Related Products Regulation (TRPR) prohibit the presence of Cadmium, Chromium, Iron, Lead, Mercury and Nickel in vape liquids. However, most of the vape devices in the case above were sold illicitly with no adherence to TRPR regulations and procured from other countries where quality standards are less stringent. In these cases, the liquids could be made from ingredients of inferior quality or manufactured in an environment where these contaminants can get into the product. These can then be smuggled into the country with little or no quality control to ensure their safety. The product can then be sold illegally to children or unsuspecting adults with high levels of heavy metals at the point of sale.

So, all countries should be forced to use high-quality ingredients, introduce controls to remove the risk of contaminants, and test the liquids to make sure those pesky metals don’t sneak in. Problem solved?

Not quite. Some studies have shown increased concentrations of heavy metals such as Chromium, Copper, Nickel, Lead, Tin and Zinc in aerosol samples generated by a vape device compared to vape liquid taken from the original packaging. So, we are getting heavy metal contamination from point-of-use. This is due to the leaching of metals into the vape liquid from the metallic elements of the vape device as it is heated. John Hopkins University demonstrated this in a study which showed that the concentrations of these metals were highest in vape liquid taken from the refill tank of vape devices compared to the original packaging and aerosol. The leaching effect could potentially be exacerbated by the fact that PG becomes more acidic as it degrades (as an analytical chemist in our trace metals team, I can confirm that heat and acid are a great way to leach metals into solution!). This is because it forms formic acid when it degrades, and one factor that can cause it to degrade is, you guessed it, heat!

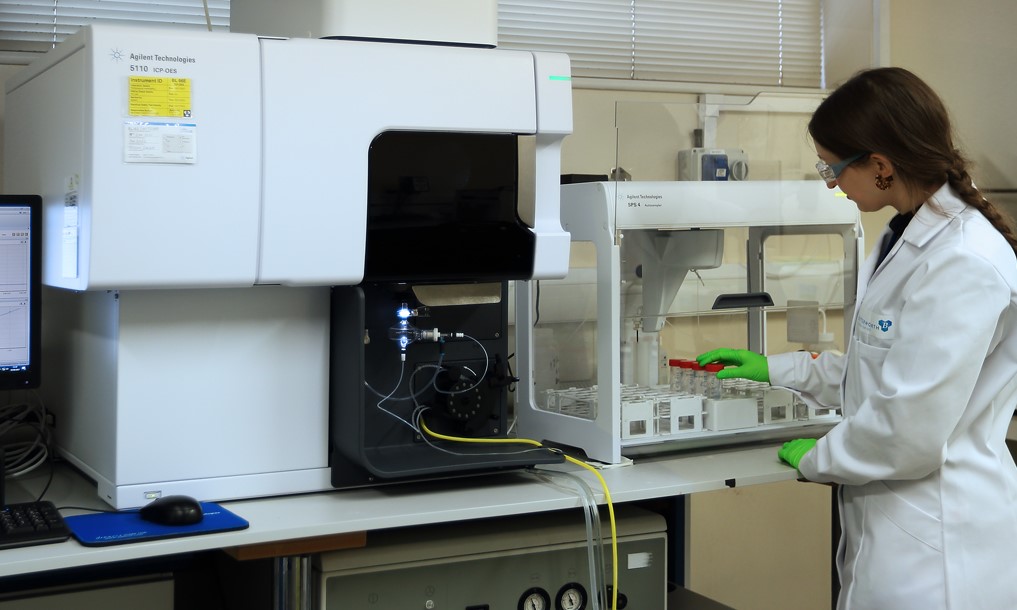

Fortunately, TRPR has already accounted for this. They require manufacturers to submit data on the levels of toxicants, such as heavy metals, generated during reasonable and foreseeable use. The concentrations of heavy metals in the liquids and emissions are generally tested via trace metal techniques such as ICP-MS and ICP-OES, which we at Butterworth Laboratories are well established with. While we do not currently perform analyses on vape liquids, we perform tests on many other products from the pharmaceutical, health & beauty, and chemical industries. However, as shown by the case in 2023, not everywhere is so diligent with ensuring the purity and safety of their products. Cases like this demonstrate why trace metal testing is so important.

Calvin-John Nicol – Analytical Chemist